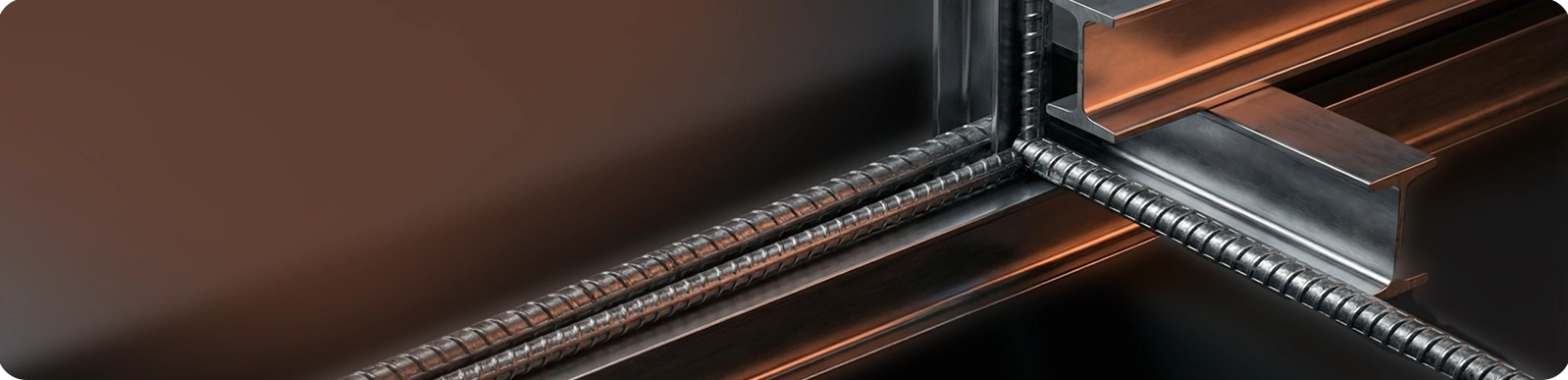

Al Madina Steel B420 DWR reinforcing steel is designed to deliver high levels of safety, durability, and performance, making it a reliable choice for modern construction projects especially those requiring enhanced structural stability.

With decades of experience in the steel industry, Al Madina Steel continues to support national development by providing reinforcing solutions that comply with Egyptian standards and meet the demands of contemporary construction systems.

Al-Madina Steel Group fulfills supply orders for steel rebar products with precise mechanical and chemical properties, conforming to Egyptian construction standards.

Bar weights and specifications according to Egyptian rebar steel manufacturing standards (ES262-2/2015), Grade B 400 B-R and B 500 B-R.

| Color Code | Length/ Meter | Weight / Max (KG) | Weight/ Per Meter | Diameter (MM) |

|---|---|---|---|---|

| Green | 12 | 7.404 | 0.617 | 10 |

| Red | 12 | 10.656 | 0.888 | 12 |

| Blue | 12 | 18.960 | 1.58 | 16 |

| White | 12 | 24.000 | 2.00 | 18 |

The actual productivity capacity of the rebar plant is 240,000 tons annually. Almadina Steel aims to enhance the productive capacity by 450,000 tons annually for the production lines (line 1- line 2), while maintaining the quality assurance system within the manufacturing process by the following:

The actual productivity capacity of smelting plant is 135,000 tons annually.

Almadina Steel aims to enhance the productive capacity up to 300,000 tons annually.

Al Madina Group has achieved many successes and a strong presence in the steel industry market.

CALL US

MAIL US

© 2026 O2Nation – All rights reserved